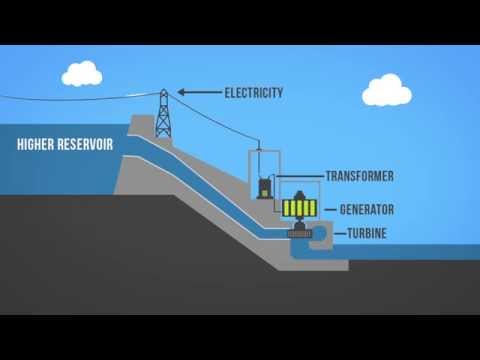

Hydro-electricity is generated either from the potential energy of water that is collected in a reservoir behind a dam or from the kinetic energy of moving water in a river or tidal current. The water spins a turbine, which is connected to an electricity generator.

Hydro electricity generation is not as reliable as nuclear power where it may be affected by drought or reduced meltwater from glaciers. Construction of a hydroelectric complex can have significant environmental impact, principally in loss of arable land and population displacement. They also disrupt the natural ecology of the river involved and dam failures can be catastrophic.

Hydroelectricity generates about 15% of global electricity and provides at least 50% of the total electricity supply for more than 35 countries. In 2021, global installed hydropower electrical capacity reached almost 1400 GW (gigawatts), the highest among all renewable energy technologies.

A hydroelectric power station that has a dam and reservoir can increase or decrease the amount of electricity generated very quickly to match varying demand. So, it is not generally used to produce base-load power, instead, it is typically used to backup variable generators like windmills. (Although battery power is quicker, its capacity is tiny compared to hydropower).

Where a dam is used to control flooding, a hydroelectric station provides a useful revenue stream to offset construction costs. The sale of electricity from the Three Gorges Dam should cover the construction costs within 8 years of full generation.

The size of hydroelectric plants can vary from small plants called micro hydro, to large plants that supply power to a whole country. As of 2019, the largest power station in the world is a conventional hydro-electric power station, the Three Gorges Dam on the Yangste river in China which has a 22,500 MW (megawatt) capacity.

History

Sometime in 4th century BCE India, farmers realized that a undershot water wheel could be driven by the flow of a river or stream, using the power to raise water for irrigation. They quickly developed the more powerful overshot wheel. For the first time in history, they had a source of power that did not depend on human or animal muscles.

The water wheel was quickly adapted to grind seeds and, later, an added crank driven saw was used cut timber, stone or marble, and trip hammers, lifted by cams, were used to crush gold bearing rock. Piston bellows, used to smelt iron, appeared in China about 30 CE.

The earliest water turbines were designed, in Tunisia, before the in 4th century CE. These used two helical-turbines, on a vertical shaft, immersed in a circular housing filled with water.

In 1595, Fausto Veranzio described a vertical axis mill with a water turbine but it was not until the 18th century that engineers developed turbines with efficiencies up to 80%. The turbines were smaller than water wheels of a similar power and could spin faster and use much greater heads (The height of water above the turbine providing potential energy (pressure)).

In 1849, James B. Francis improved the inward flow reaction turbine to over 90% efficiency and the Francis turbine became the most widely used water turbine in the world today.

The modern fluid bearing, used to support heavy water turbine shafts, was invented about 1890 and Viktor Kaplan devised a propeller-type turbine that permitted the development of high flow, but low-head, hydro sites.

In 1866, California millwright Samuel Knight, developed a bucketed wheel, powered by the kinetic energy of a jet of water powered by from a high pressure head (hundreds of vertical feet in a pipe or penstock). In 1879, Lester Pelton, used double buckets which exhausted the water to the side and about 1895, William Doble achieved up to 92% efficiency using elliptical buckets to provide a smoother bucket entry for the jet.

Most water turbines are reaction turbines used in large power plants with low to medium head hydro stations up to 100 m 300 ft. Impulse turbines, like Pelton wheels, change the velocity of a water jet which pushes on the wheel's curved buckets. Impulse turbines are typically used for very high (up to 300m/1000 ft) head supply.

Some water turbines (typically Deriaz or Francis turbines) are used for pumped-storage hydroelectricity; they can reverse flow to fill a higher reservoir (using off-peak electrical power generated by wind, solar and nuclear stations) and then revert to a water turbine for power generation during peak electrical demand.

YOU ARE READING

Atmospheric

Non-FictionThe eruption of Tonga's underwater volcano, in January 2022, vaporized 150 million tons of seawater and shot a geyser of super heated steam through the stratosphere. The water vapour, a strong greenhouse gas, may increase global temperatures for at...